Flooring is easily affected by moisture. Both wood flooring and concrete subfloors can be severely, perhaps even irreparably, damaged by prolonged exposure to moisture. Many flooring specialists use moisture meters to detect potential problem areas in a structure so that they can prevent flooring failures caused by moisture.

The Source of Flooring Failures

While flooring failures often create visible signs, such as cracking or buckling, the moisture causing this damage often remains hidden under floors and subfloors.

Additionally, subfloor moisture in concrete slabs can damage wood floors, and cause adhesive and coating failures. Since many commercial properties utilize a concrete subfloor, this type of damage can lead to extensive and expensive repairs.

Improper moisture content in flooring is often the underlying cause of these unsightly defects in floors, and it can be difficult, if not impossible, to detect excess moisture without the proper tools. When checking for the moisture content in floors and subfloors, many industry experts choose to use moisture meters. These powerful tools, which are far more reliable than evaluations made using only the naked eye, accurately identify moisture pockets that can lead to flooring failures and allow them to nip the problem in the bud before it becomes an emergency.

Moisture Meters and Flooring Failure

Many flooring specialists have found improved success by using moisture meter technology in their work. These tools can detect the sources of moisture with a high degree of accuracy, and significantly reduce the chances of failure for most flooring operations. There are three types of meters that are commonly used in flooring moisture detection: thermo-hygrometers, pin-type moisture meters and pin-less moisture meters.

Thermo-Hygrometers

Thermo-Hygrometers

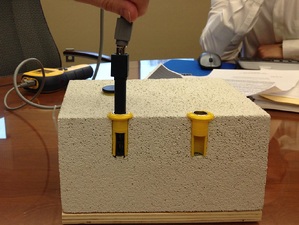

These are the ideal tools to measure the relative humidity (RH) in concrete. It’s important for flooring specialists to accurately measure the concrete subfloor, as improper RH levels in concrete play a major role in flooring failure. When used to measure the relative humidity of concrete, they are also referred to as RH meters. RH meters with in-situ probes are used both prior to the installation of a top floor or coating and during inspection if there is a claim after installation. These devices are very useful when predicting the way a concrete slab will behave.

Pin-type Moisture Meters

Pin-type Moisture Meters

Pin-type moisture meters are the industry-preferred tools for identifying exact moisture levels in an affected or damaged location. These moisture meters operate on the principle of electrical resistance. The user of a pin-type moisture meter pushes two pins into the object to be measured. Once the pins are in, the user turns the meter on, causing one pin to generate an electrical current. The other pin receives the current, and the meter displays a value on-screen for the amount of resistance there was to the electric current between the electrodes. Since water is a conductor, the less resistance there is, the more water is present in the object being measured. Many flooring specialists use pin-type meters to accurately measure moisture at different penetration levels, which allows them to measure the extent of a floor’s moisture content and the chances of a flooring failure.

Pin-Less Moisture Meters

Pin-Less Moisture Meters

These moisture meters are efficient tools when used to scan large areas for improper moisture content. These meters use a radio frequency instead of pins to detect moisture, and do not physically affect a floor surface when used. This comes at a cost, however, as these meters are less able to detect precise moisture content in a given spot. However, they are better able to scan larger areas for the presence of excess moisture. This wider scope makes them ideal for identifying problem areas quickly, rapidly finding areas that are at high risk for a flooring failure.

Combining Multiple Meters

Many flooring professionals detect flooring failure using a combined application of pin-less and pin-type meters for wood flooring, and thermo-hygrometers for concrete subfloors. This approach effectively identifies problem areas in flooring, and still details the precise extent of moisture content. With accurate moisture readings, industry specialists can make more appropriate repair decisions, going beyond surface damage and assessing a flooring failure’s source.

Additionally, the information moisture meters provide can be used as a preventative resource prior to flooring installation. Many occurrences of floor damage and failure can be easily avoided using the information provided by proper floor moisture meter readings prior to, and during, installation. A moisture meter in your flooring toolbox can help provide assurance of a job well done for long lasting results.

Proactive moisture detection can save both you and your customers significant amounts of time and money, averting the need for major renovations and flooring replacements. To learn more about the role of moisture meters in detecting flooring failure, or the many ways these meters can improve your flooring business, contact us today.

Comments