As the proprietor/manager of a flooring supply store, you know that your business’ success rides on your customers — their success, their happiness with your products/services, and your ability to upsell them more products and/or services. Whether you specialize in tile, wood, or carpet flooring (or all three), finding ways to delight your flooring customers and keep them coming back for more is enormously important.

As the proprietor/manager of a flooring supply store, you know that your business’ success rides on your customers — their success, their happiness with your products/services, and your ability to upsell them more products and/or services. Whether you specialize in tile, wood, or carpet flooring (or all three), finding ways to delight your flooring customers and keep them coming back for more is enormously important.

The odds are that you’ve already done a lot to attract repeat business — updating your stock of flooring materials, reaching out to local customers through targeted ad campaigns, building relationships with local flooring contractors, etc. However, there is one other, more unusual thing you can do to help your customers and boost your business: offer your flooring customers flooring moisture meters and thermo-hygrometers that they can use on the job.

Why carry moisture meters for flooring? The answer is in the benefits that such moisture testing devices offer to both your customers and your business:

1: Helping Make Your Business a “One-Stop” Shop for Flooring Supplies

Moisture meters are a critical control for many flooring installation projects—particularly those involving wood. Additionally, thermo-hygrometers are a core component of the ASTM F-2170 concrete moisture testing standard. By carrying moisture meters, thermo-hygrometers, and in-situ probes for your flooring customers, you can meet some of their more specialized needs and turn your store into a true “one-stop” shop for their needs.

By becoming a one-stop shop for your flooring customers’ needs, you can help ensure that they come to you first whenever they need something flooring related.

2: It Gives You Opportunities to Upsell Your Customers

Because moisture meters are a critical part of ensuring top-notch quality and safety for flooring installation work, they make for a natural upsell opportunity during any flooring product transaction.

For example, say that a customer is buying a bunch of hardwood flooring for a major installation project. Here, a wood moisture meter would be the perfect add-on for the sale so the customer could verify that their hardwood is at equilibrium moisture content (EMC) for the installation environment before they install it. This way, they can avoid issues such as buckling, cupping, and warping that occur when wood isn’t at EMC prior to installation.

Even if the customer has a moisture meter, there may be optional electrodes, replacement pins/scanning plates, moisture content standards, and other accessories that could help make testing for moisture in their flooring easier.

Alternatively, contractors might need to acquire a thermo-hygrometer, in-situ probes, and probe sleeves to carry out ASTM F-2170 standard-compliant testing of their concrete.

3: They Help Your Customers Improve Their Work Quality

Moisture meters are a critical tool for professional flooring installers for many reasons. The biggest reason is that moisture meters help to ensure top-quality flooring installations.

For example, wood is a hygroscopic material, meaning it will absorb and release water until it reaches an equilibrium with its surroundings. When hardwood floors are installed with too much or too little moisture, it can lead to a variety of quality issues, such as:

- Cupped Floors. Wood that absorbs water will start to swell. If hardwood flooring swells too much, the individual boards can push against one another. When this causes the edges of a board to rise higher than the center of the board, this is called cupping.

- Crowning Floors. The inverse problem of cupping is crowning, wherein the center of the board rises higher than the edges. This can happen if a cupped board that has been sanded down to be flat starts to lose moisture as well.

- Warping/Buckling. This often happens when excess moisture in subfloors seeps into the wood flooring above. Here, the swelling of the wood is so severe that it starts to pull away from the subfloor, creating warped, wavy, and loose floorboards.

None of these are desirable in hardwood flooring installations. Even water-impervious (or vitreous) tile flooring can suffer negative effects if installed over a “wet” concrete subfloor as moisture from the subfloor impacts the adhesive used to secure the tile flooring.

By using moisture meters to test hardwood floors, and thermo-hygrometers to test concrete subfloors, your flooring customers can minimize the risk of moisture problems affecting the flooring systems that they install. This improves the quality of their work, helping them protect and enhance their own professional reputations.

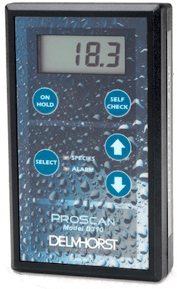

Which moisture meters should you stock to best help your flooring customers? Contact Delmhorst Instrument Co. for more information and resources that can help you meet your customer’s needs!

Comments