Another year, another successful NWFA Wood Flooring Expo! This year I presented “How Moisture Claims Can Drown Your Profits” educational seminar to a full house of over 100 professionals interested in learning how they can improve their wood flooring installation or inspection business by having a better understanding of on the job moisture matters.

The topic spurred a great discussion about effective use of moisture meters so we thought it would be valuable to share the key takeaways with those who were unable to attend.

Flooring Failures + Callbacks + Lost Time = Lost Profits!

Some estimates indicate that moisture related issues account for an astounding $1billion in flooring failures and claims. How can you prevent these failures and the associated loss of profit? One way is to use a moisture meter to:

- Measure moisture content (MC) in the wood floor and the subfloor

- Assess water damage

- Test relative humidity (RH) and moisture in concrete

- Monitor the curing process

- Determine equilibrium moisture content (EMC) and optimum conditions

Ideal Conditions for Installation

Wood is hygroscopic. When exposed to the air it will lose or gain moisture until it is in equilibrium with the humidity and temperature of the air. Because of this, wood flooring needs to be installed at the MC where it will not change dimension or experience defects.

Wood is hygroscopic. When exposed to the air it will lose or gain moisture until it is in equilibrium with the humidity and temperature of the air. Because of this, wood flooring needs to be installed at the MC where it will not change dimension or experience defects.

This optimum level of temperature and RH is referred to as the equilibrium moisture content (EMC). To measure RH you’ll need a thermo-hygrometer, as equally an important tool to have on hand for an installer as a moisture meter.

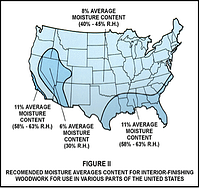

EMC varies across the country though 6% – 9% will cover most areas of the US. Wood subfloor should be within 2% - 4% MC of the flooring being installed.

Moisture Meter Types – Pin vs. Pinless

Pin meters have electrodes that penetrate the wood to measure the electrical resistance or current between two points of contact. They use the relationship between the DC resistance and the MC of the wood. Measuring with a pin meter will provide accurate estimate of average MC, give a good idea of the moisture gradient, and identify whether the source of moisture is the top floor or the subfloor.

Pinless meters transmit electromagnetic wave energy into the wood to detect the influence on moisture as an estimate of MC. It does this by sending a radio frequency (RF) wave into the wood but models may differ in frequency and electrode design. In the building trades, they are excellent tools for gaining an overall sense of the moisture condition.

Factors That Can Affect a Meter Reading

Because meters provide indirect measurements, the accuracy and reliability of their readings are subject to a number of factors. The major ones are outlined in an effort to help you decide which type best suits your needs.

|

|

Pin Meter |

Pinless Meter |

|

Wood species |

|

|

|

Specific gravity (density) |

|

|

|

Wood temperature |

|

|

|

MC Range |

|

|

|

Surface moisture |

|

|

|

Sample size (width and thickness) |

|

|

Moisture Meters for Flooring

Moisture meters and thermo-hygrometers are proven, indispensible tools for flooring inspection and installation. To achieve fast, accurate results you must know the meter’s capabilities, follow the manufacturer’s procedures and, most important, apply your knowledge and experience.

Comments